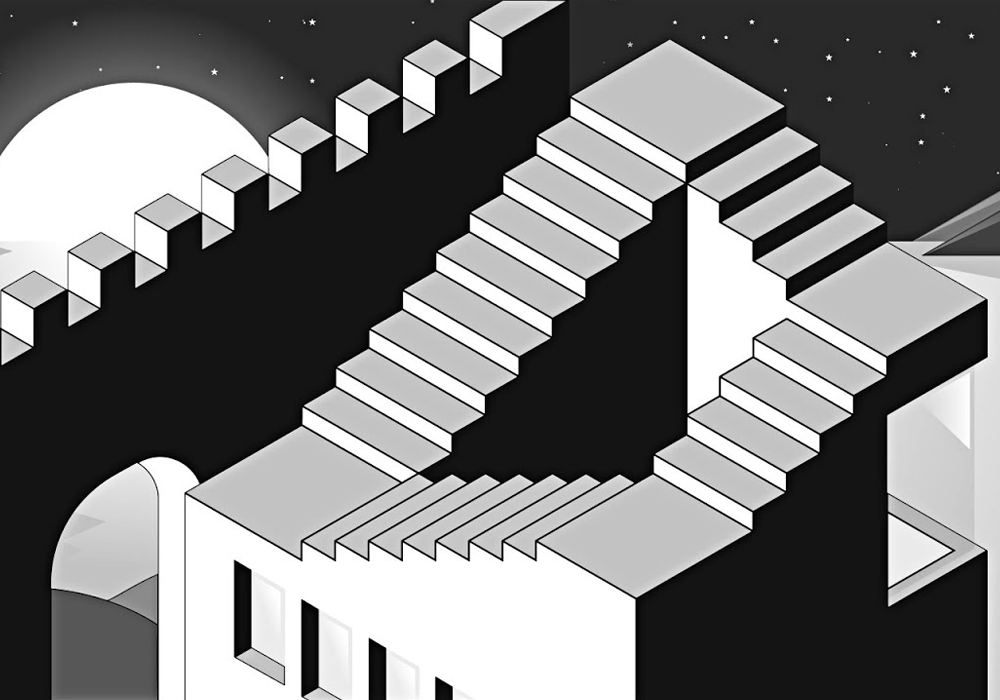

The Illusion of Strategy: A Day at the Strategic Meet

— A Leadership Reflection on Purpose, Alignment, and Impact It was a usual start to the day, except that this wasn’t an ordinary day. The chairs were neatly arranged, the projector was already humming, and there was an anticipatory energy in the room. I had not originally planned to be here. My schedule suggested I’d […]

Explore More