The Illusion of Strategy: A Day at the Strategic Meet

— A Leadership Reflection on Purpose, Alignment, and Impact It was a usual start to the day, except that this

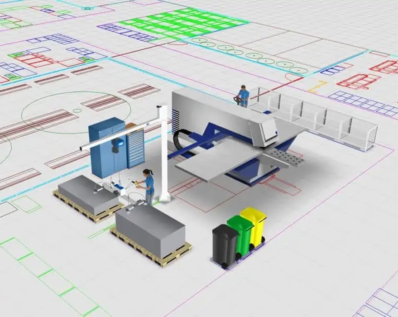

The Silent Efficiency Killer: Why Factory Layout Design Matters More Than Ever

In today’s highly competitive manufacturing landscape, companies invest heavily in defining processes, creating detailed Standard Operating Procedures (SOPs), deploying modern

Business Strategy Implementation: Common Roadblocks and How to Overcome Them

Implementing a business strategy is often more challenging than creating one. While defining a clear strategic vision is essential, effective

Standard Operating Procedures (SOPs): A Foundation for Innovation, Not a Barrier

Debunking the Myth: “SOPs Kill Innovation” In a recent conversation with a CEO, a common concern was raised — that

Sustaining Continuous Improvement: The Key to Long-Term Business Success

Why Sustaining Continuous Improvement is a Challenge One of the most challenging aspects of implementing best practices in any organization

TFM (Total Flow Management): Meaning, Purpose, Benefits, Method, Application, and Example

Total Flow Management (TFM) is a comprehensive approach aimed at managing the flow of materials, information, and products throughout an

TPM (Total Productive Maintenance): Meaning, Purpose, Benefits, Method, Application, and Example

Total Productive Maintenance (TPM) is a proactive maintenance strategy designed to improve the reliability and efficiency of production equipment by

Heijunka: Meaning, Purpose, Benefits, Method, Application, and Example

Heijunka is a key concept in lean manufacturing, particularly within the Toyota Production System (TPS), aimed at leveling production. It

SMED (Single-Minute Exchange of Dies): Meaning, Purpose, Benefits, Method, Application, and Example

SMED is a lean manufacturing technique aimed at reducing the time it takes to change over equipment or processes, thus

Total Quality Management

(TQM) is a comprehensive and structured approach to organizational management that seeks to improve the quality of products and services

What is Hoshin Kanri?

Hoshin Kanri is a strategic management methodology used to align an organization’s goals, vision, and resources to ensure that all

Six Sigma: Meaning, Purpose, Method, Application, Benefits, and Example

Six Sigma is a data-driven methodology aimed at improving business processes by identifying and removing defects and variations, ultimately enhancing

Value Stream Mapping (VSM): Meaning, Purpose, Benefits, Method, Application, and Example

Value Stream Mapping (VSM) is a visual tool used to analyze, design, and improve the flow of materials and information

Jidoka: Meaning, Purpose, Benefits, Method, Application, and Example

Jidoka is a principle of the Toyota Production System (TPS), often referred to as “autonomation” or “automation with a human